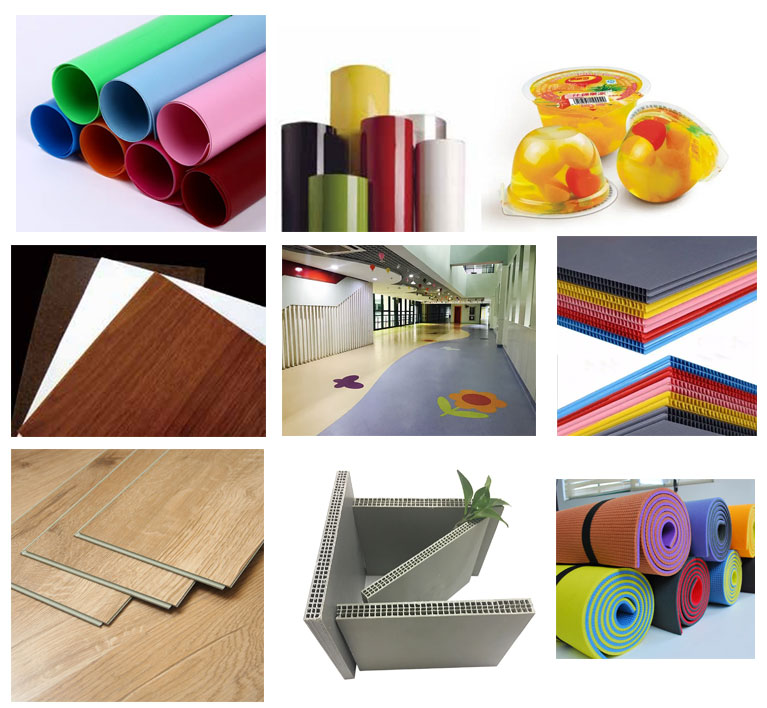

Material: PC, TPO, PP, PLA, PP, PS, EVOH, ABS, HIPS, PE, PVC, ASA, EVA, PMMA, GPPS, SPC, LVT and etc.

Nominal width: 400-3000mm

Thickness: from 150 microns for foils up to some centimeters for sheets or multicellular panels

Output: up to 1400kg/h

Food Packing:

The extrusion line has the properties of low energy consumption, a simple production process, and easy maintenance. The segmented screw structure can reduce the viscosity loss of resin, and the symmetrical and thin-wall calender roller heightens the cooling effect and improve the capacity and sheet quality. Multi components dosing feeder can control the percentage of virgin material, recycling material, and masterbatch precisely, the sheet is widely used for the thermoforming packaging industry.

Materials: PET, PS, PE, PP, EVA, EVOH

Environmentally Degradable Sheet:

The production process of PLA is non-polluting, and the product can be biodegraded to achieve circulation in nature, so it is an ideal green polymer material. PLA has good thermal stability, processing

the temperature of 170-230℃, with good solvent resistance. Products made of PLA have the advantage of biodegradability, gloss, transparency, good feel, and heat resistance. It also has good antibacterial, flame retardant, and UV resistance.

Material: PLA (Polylactic Acid)

Multilayer high barrier sheet:

JWELL developed advanced technology of 5-layer symmetrical distribution and 7-layer asymmetrical distribution, which makes the produced sheets have better barrier performance, excellent anti-oxygen, and anti-humidity. Mainly used for Jelly packing, meat packing, snack food packing and etc, medicine and cosmetic packing.

Material: PP, PS, EVOH

Multicellular panels:

On the basis of the traditional production line, that not only could meet the demand of large output and low energy. Mainly used in building construction.

Material: PP, PVC, PC

Decoration:

SPC composite floor extrudes by PVC’S base material get through four-roll calender machines, and PVC color film + PVC wearing layer + PVC basis of the membrane, next press and paste these films to be products, simple process, complete the paste that depends on heat, there is no glue.

Material: PVC, SPC, LVT

Furniture industry:

Single or co-extruded sheets for panels covering domestic furniture. Also for edge bands production, with wood grain surface embossing, primer coating, and printing with a UV drying system.

Materials: ABS, PMMA, PVC, PP.

Refrigerator industry and bathroom furnishing:

Single or co-extruded sheets to be thermoformed for refrigerator doors or bathroom furnishings such as shower pans, basins, bathtubs, etc. Surface treatment for foam application, bright and glossy finishing. Automatic cutting and stacking.

Materials: PS (HiPS and GPPS), ABS, PMMA

Medical bags:

Various types of extracorporeal circulation systems, interventional treatment systems, etc. The products used are medical infusion bags, waste liquid bags, hemodialysis (window) bags, breathing masks, etc.

Materials: PVC, EVA

Automobile:

Automobile interior skin composite materials are used in the interior of mid-to-high-end automobile instrument panel skins,

automobile side door panels, seats, and other interiors. This production line can realize online composite embossing and

one-time shaping. It has the advantages of high production efficiency, firm composite bonding, and convenient pattern modification.

Materials: PP, TPO, PVC.

Specialty execution:

XPE, IXPE foam sheet, bag lining, packaging of the integrated circuit board, sole of advanced sports shoes, cushion and heat insulation for cars, decoration material, floating material, single or double coat adhesive tape, and so on.

ASA film is widely used in roof tile fields. In the process of roofing

tile, it can achieve online thermal composite, with uniform thickness, no color difference, and high bond strength. It overcomes the color difference of traditional coextrusion ASA composite, and also deals with the cost of raw materials.